We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

JUKI DLU-5490N-7-WBAK85/PF6 1 NEEDLE BOTTOM & VARIABLE TOP FEED LOCKSTITCH MACHINE AUTO THREAD TRIM

Juki DLU-5490N-7

1-needle, Bottom and Variable Top-feed Lockstitch Machine (with automatic thread trimmer)

With its bottom and variable top-feed mechanism, the machine widely adapts to diversified applications and helps promote the production of upgraded-quality products while increasing efficiency.

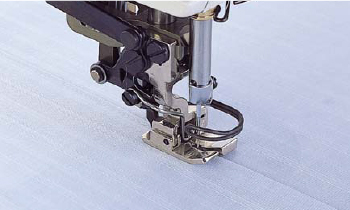

The durability of the walking foot has been dramatically improved

The walking foot provides stable feed at all times, assuring high quality. It also eliminates the need for proficiency.

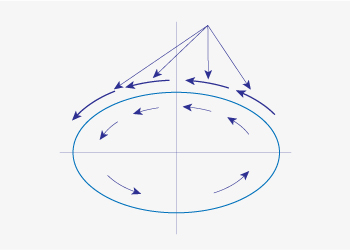

Ideally balanced top feed and bottom feed

The top feed motion ideally synchronized with the bottom feed motion to uniformly feed the upper and lower cloths, assuring attractive stitches and uniform gathering stitches.

This leads to a higher value of finished products.

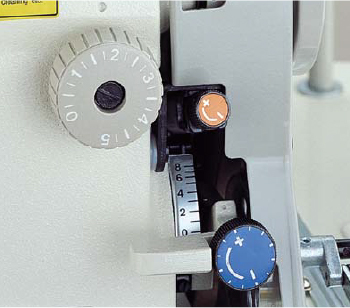

The maximum top feed amount is 8mm

The top feed amount has been increased to assure stable gathering stitches.

Higher lift of the presser foot

The large lift of the presser foot enables the operator to easily set or remove materials and sew overlapping sections without any difficulty.

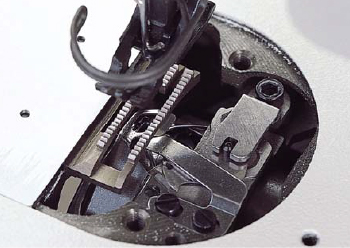

Sure thread trimming mechanism

The machine comes with a thread trimming mechanism that performs speedy and sure thread trimming to achieve highly efficient sewing work.

Newly developed control box/Compact-size servomotor (SC-920C/M92)

The new model control box, which energy-saving mode is provided. The new model control box SC-920C has been newly developed. The control box is resistant to voltage fluctuations, noise and vibration.

The new model control box is provided with an energy-saving mode for the first time in a control box for sewing machines.

It reduces power consumption during standby time when the motor is not rotating by approximately 25% (in comparison with the SC-910N).

In addition, the current DLU-5490N is lavished with the latest energy-saving technologies,including the adoption of the latest compact servomotor M92, to be more friendly to theenvironment, as well as to provide the power reducingeffect and to increase productivity.

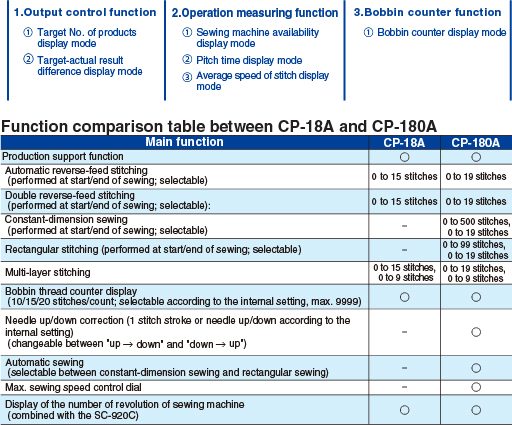

The operation panel can be selected according to the process (CP-18A, CP-180A)

Two different operation panels, the CP-18A and CP-180A are applicable to the DLU-5490N-7. Both operation panels are provided with the production support function.

The production support function actually consists of three different functions (six different modes)

Technical Specifications

| Model | Juki DLU-5490N-7 |

|---|---|

| Max. sewing speed | 4,500sti/min* |

| Max. stitch length | 5mm |

| Max. top-feed amount | 8mm |

| Needle bar stroke | 30.7mm |

| Lift of the presser foot | By hand: 5.5mm, By knee: 13mm |

| Needle (at the time of delivery) | DB×1 (#14), For JE: 134 (Nm90) |

| Hook | Automatic-lubricating full-rotary hook |

| Lubrication | Automatic |

| Lubricating oil | JUKI New Defrix Oil No.1 (equivalent to ISO VG7) |

| Automatic reverse feed function | Provided as standard |

| Power requirement | Single-phase 100~120V, 200~240V 3-phase 200~240V |

| Power consumption | 650VA |

| Weight | Total weight: 83kg |

*“sti/min”stands for“ Stitches per Minute”

| Part No | JUKIDLU5490N7 |

|---|---|

| Weight (KG) | 0.100000 |

| Fabricant | Juki |